When Justin Hornung ‘27O&P started working in Orthotics and Prosthetics (O&P) program, he realized the amount of plastic being wasted in the profession was something widely known but seldom discussed.

So, alongside his schooling, he decided to investigate the growing amount of plastic waste. When researching the topic, Hornung learned some of the nuances and difficulties that come with trying to reduce the amount of plastic waste in the profession. This sparked a research project aimed at raising awareness of the issue and inspiring future researchers to pursue solutions to the growing plastic problem.

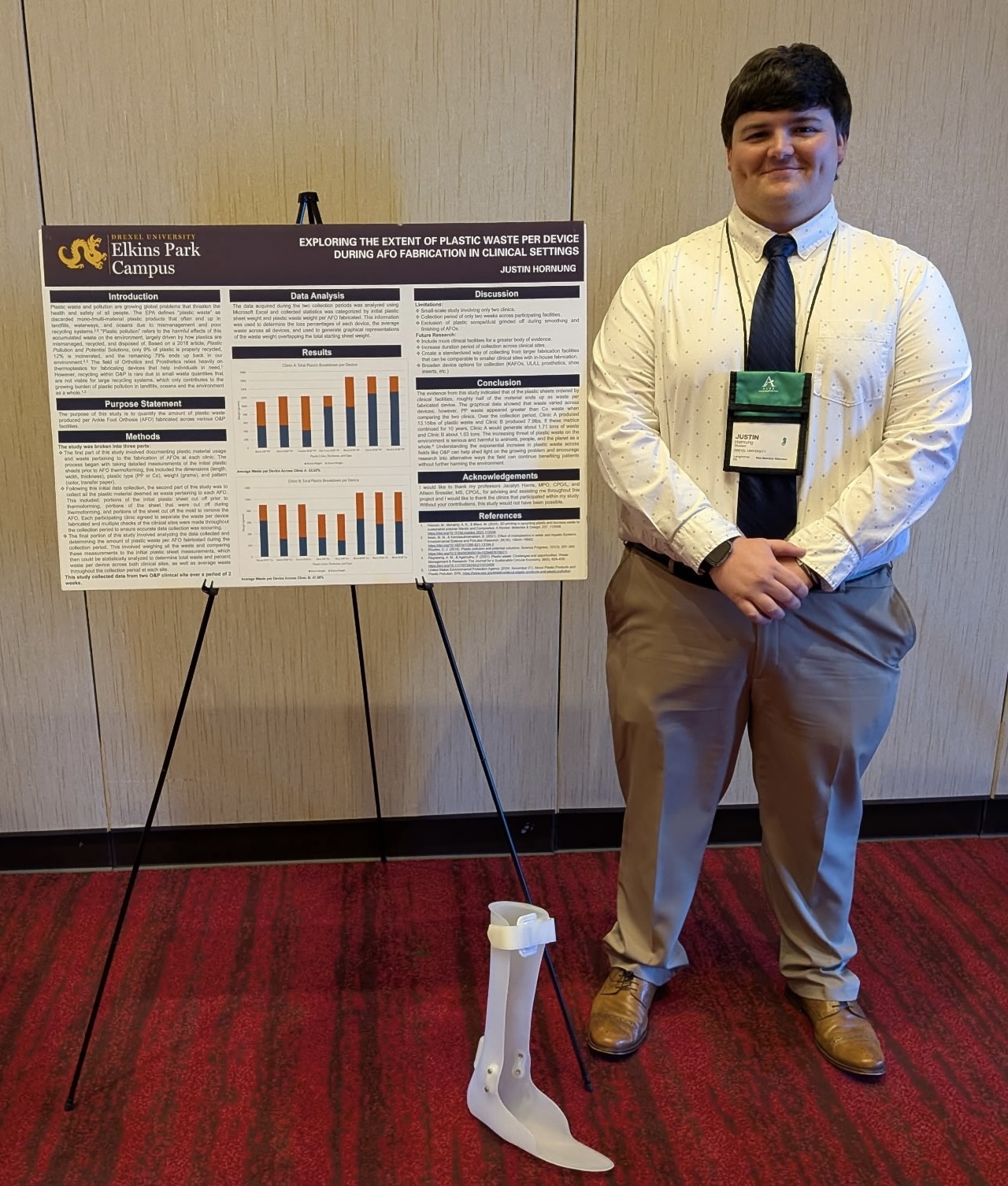

Through his research, Hornung’s study became eligible for recognition and attention. His research turned into a poster presentation titled “Exploring the Extent of Plastic Waste Per Device During Ankle Foot Orthosis (AFO) Fabrication in Clinical Settings,” which recently tied for first place at the regional meeting of the New Jersey Chapter of the American Academy of Orthotists and Prosthetists in Atlantic City, New Jersey.

At that meeting, O&P students from the Drexel University Elkins Park campus and the University of Hartford presented poster presentations and were judged on their innovative and clinical contributions.

At that meeting, O&P students from the Drexel University Elkins Park campus and the University of Hartford presented poster presentations and were judged on their innovative and clinical contributions.

“The students continue to impress me with their innovative ideas and forward-looking perspectives,” said Jacalyn Harris, MPO, CPO/L, assistant professor in the Drexel O&P program. “Justin's project was well thought out and executed, and brings forward the important topic of sustainability in the profession. It exemplifies his holistic view of patient care as well as the impact we have on the world around us.”

For his research, Hornung collected plastic waste over two weeks from two participating clinics based on the AFOs fabricated. He then used the collected information to compare the weight of waste to the initial plastic sheet weight used for each AFO. This allowed him to calculate different waste percentages across both clinical facilities for each device.

What Hornung found was on average, 50 percent of the plastic sheet used to make an AFO ends up as waste during the fabrication process. “I was shocked at first when I heard my poster had won, but mostly I felt grateful and proud,” he said. “It was really meaningful to be acknowledged for all the effort I put into my project, and I was happy to see that others enjoyed hearing about it as much as I enjoyed working through it.”